Stable Irrigation System Senior Capstone Project

- Zackary Roth

- Dec 20, 2022

- 3 min read

Updated: Dec 23, 2022

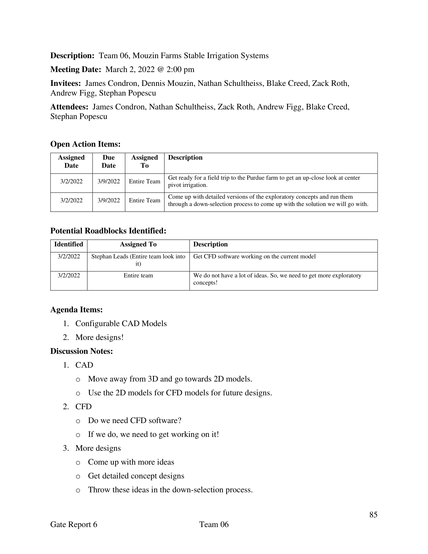

For the Spring semester of the 2021-2022 school year and the Fall semester of the 2022- 2023 school year, 3 other students and myself were assigned to work with the client Mouzin Brother’s Farms and engineer a possible solution that will stabilize center-pivot irrigation systems used in their fields. Center-pivot irrigation systems are pieces of farming equipment used throughout the United States and around the world for dousing large areas of farming land with water. The challenge this group was assigned to attempt to overcome is the issue of these irrigation systems’ propensity to catch strong, perpendicular gusts of wind during large storms. As a result, these systems can be twisted and blown over causing severe damage to the center pivots as well as the crops. The developed solution to improving the center pivot irrigation system’s resilience against storms and high-speed winds helps save farmers money from unanticipated repairs or replacements and lost or damaged crops. This stability solution also helps farmers with insurance premiums.

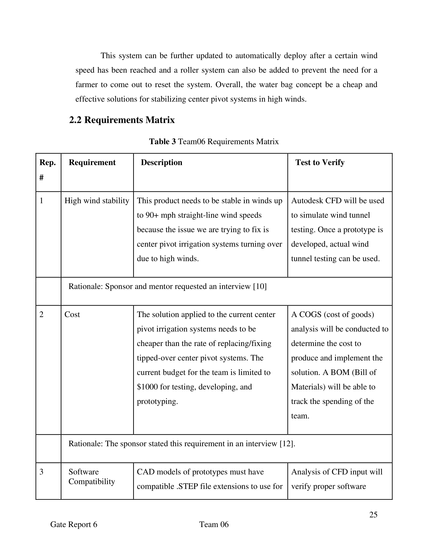

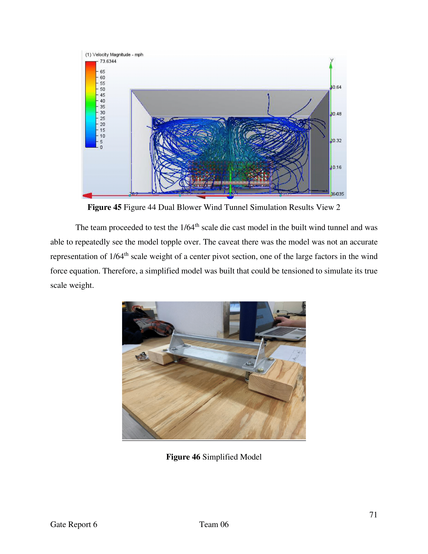

The team has researched existing solutions and patents and has designed a theoretical solution for the client’s desires for their own center pivots. The team developed the solution from Computer-Aided Design (CAD) and was tested using Computational Fluid Dynamics (CFD) software. The CFD determined the effectiveness of the final concept by comparing results from the current center pivot model in high winds. In conjunction, the team constructed a physical wind tunnel to confirm the simulation results on a 1/64th scale model.

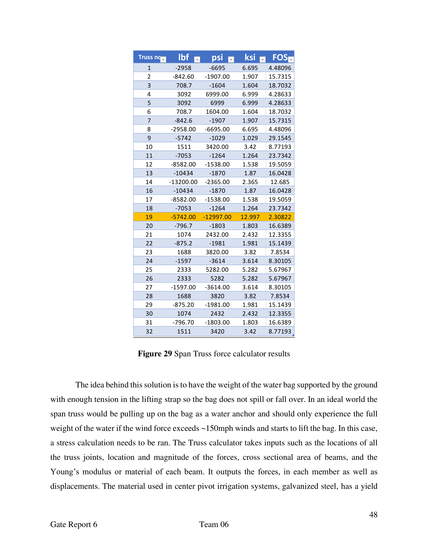

The team was able to elude that lift was generated on the current standard model of center pivots and that their theoretical solution of a water bag anchor in the center of the pivot in addition to a wider base with structural cables attached to the center (dubbed the spider design) eradicated the lift and made the pivot significantly more stable in high winds. In addition, the team was able to justify simulation results by creating a physical model of testing and recreating said models in the same software. There was no plan to go full-scale with the team’s proposed solutions. Actual implementation on a center pivot should fall to the manufacturer and their research and development teams in the future alongside the transition from a theoretical design to a ready-to-manufacture design. Overall, the wind tunnel, and simulations the team constructed were ready to be a deliverable to hand off to the client for them to take to their supplier and have a conversation about the development of additional augmentations to their lineup of center pivot irrigators.

Below is the entire 102-page report! You are welcome to slide through the pages or download the document for an easier read. In addition, I have added a video demonstrating the CFD simulations and a video summarizing our project.

In addition, to being the team lead for the project one of the biggest highlights was the learning of CFD analysis. I have dabbled with computational fluid dynamics in my previous fluid controls class at Purdue but not to this extent. For this senior capstone, I was the one who tackled the simulation side of our analysis and was able to successfully run multiple wind simulations. I was not only able to simulate scale models of center pivots in 100mph linear winds but was also able to simulate the team`s physical wind tunnel to justify the accuracy of the results from said simulations. Overall, I can go on and on about this two-semester-long project and my learnings but want to conclude this post by saying it was a wonderful/challenging experience.

Comments